National manufacturing industry plans for the next decade clearly put forward to vigorously develop energy-saving industries, and actively use energy-saving new technologies, new products, new technology, new materials, manufacturing development into new vitality. Midsummer is approaching, but also to the peak period, many plastic companies will face a new round of energy-saving pressure.

In response to home energy policy, following the Guangdong Dongguan and Wuhan, Wuhan, Fujian is the third start of thousands of injection molding machine energy-saving renovation project of the city, this initiative is spread out in the country. At the same time, this is also the implementation of green development strategy, building a resource-saving and environment-friendly society development must pass through. Injection molding enterprises to actively change the strategy, the use of advanced energy-saving equipment to enhance the competitiveness of enterprises.

Electric heating ring is an indispensable part of the heating part of the injection molding machine barrel. As the injection molding machine electric heating system accounts for 15% ~ 30% of the energy consumption of the whole machine, if the different kinds of electric heating ring can be used reasonably, the energy consumption can be reduced , Thereby reducing production costs. At present, the market popular heating circle three: resistive electric circle, electromagnetic heating ring and nano infrared electric circle.

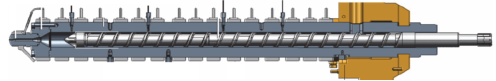

Injection molding machine cylinder diagram

'

Resistive heating rings need to overcome the resistance of the conductor to convert electrical energy into heat and transfer through contact conduction, resulting in a lot of heat dissipated into the air, low thermal efficiency, high ambient temperature.

Electromagnetic heating is generated by LC parallel resonance, through the barrel cutting magnetic field lines, resulting in eddy current to heat the plastic melting. Electromagnetic heating technology is through the electromagnetic induction principle of the metal barrel itself heat, and according to the specific circumstances in the barrel outside the package of a certain thickness of the insulation material, thus greatly reducing the heat loss, improve the thermal efficiency, so energy-saving effect Very significant. On the other hand, the electromagnetic induction heating ring is composed of high frequency current through the coil to produce high-speed alternating magnetic field, when each section of the electromagnetic heating coil by power, the magnetic flux density will be significantly increased, when the magnetic field strength reaches a certain amount Will pose a hazard to the central nervous system of the human body. In addition, the electromagnetic induction heating ring generated by the harmonic harmonics on the grid there is harmonic pollution, the impact of power grid, resulting in increased power loss of the power grid, equipment, shortened life and unsafe operation. At the same time, the electromagnetic heating also on the surrounding precision instruments have adverse effects, such as temperature thermocouple, displacement sensor, injection molding machine controller, there will be temperature fluctuations, the location of beating, the controller out of control and so on.

Nano infrared electric circle is generally composed of nano electric heating layer, insulation layer, shell, radiation coating and other components. After the exchange of electricity, the electric circle itself into a far infrared radiation heat source, heat conversion rate of 98% or more. In addition, the unique one-way heating design can firmly lock the heat, to prevent the distribution to the air, significantly reduce the working environment temperature. As the resistance heating ring and infrared heating ring are all hot-type heating ring, does not produce harmonics, no adverse effects on the grid.

It can be seen that the energy saving rate is not the only reference standard for the comprehensive energy efficiency of the electric heating circle. The safety is also an important factor that the injection molding machine enterprise can not ignore when making the purchase decision. In the electric energy on the basis of energy-saving, combined with the current advanced servo control technology, injection molding machine performance will be a big leap in the practical sense.

Can be the original as the overall energy-saving areas of the core competitiveness of enterprises, has been committed to providing customers with the best energy-saving solutions. With expertise and years of experience in transformation, we have formed energy-saving products such as energy-saving product development, energy testing, sales and installation as one of the product value chain, business coverage motor systems, drying systems and air conditioning systems and other energy-saving areas. Customers include hundreds of large and medium-sized enterprises, including Coca-Cola, the United States Group, Changhong, Colgate, Formosa Plastics Group, China Southern Power Grid (EMC), and other famous enterprises. As an innovative enterprise, the original will continue to lead the trend in the field of energy-saving services.